For a couple of years now on my street, the Plaza de Cascorro in Madrid, a 3D printing shop called TR3SDLAND has been open. My curiosity has led me to explore the shop and its services a few times,  but I haven’t encountered a compelling need to actually use any 3D services and get some practical experience with the 3D scene.

but I haven’t encountered a compelling need to actually use any 3D services and get some practical experience with the 3D scene.

Fortunately, I found out that friend of mine, Frederico Collada, editor of Blitzscales Modelling Magazine, could tell me all I really needed to know about 3D printing. What follows is a summarized synopsis of his views, augmented by a bit of my own secondary research:

There won’t be 3D printers in every home and business

There exists the general idea that in the future, not too far away, we will all have our 3D printers at home and download all the files we want to print anything. However, though prices are coming down, the complexities of 3D printing mean that it will never make sense for everyone to own their own machine. The reality is, and will continue to be, that each printer has a certain set of capabilities and limitations (more on that below) that makes it essentially impossible to have one versatile machine that can do it all. The opposite is true – printers are becoming more specialized and so the prevalent current model of having specialized shops and service providers that have dozens, or hundreds, of printers of different types for different purposes, known as printer farms, will continue and provide the versatility, scale and efficiency that individual printers will never be able to deliver.

Prusa 3D Printer Farm – source: Solidsmack

3D Printing is not only important for the Future, but also for the Here Now

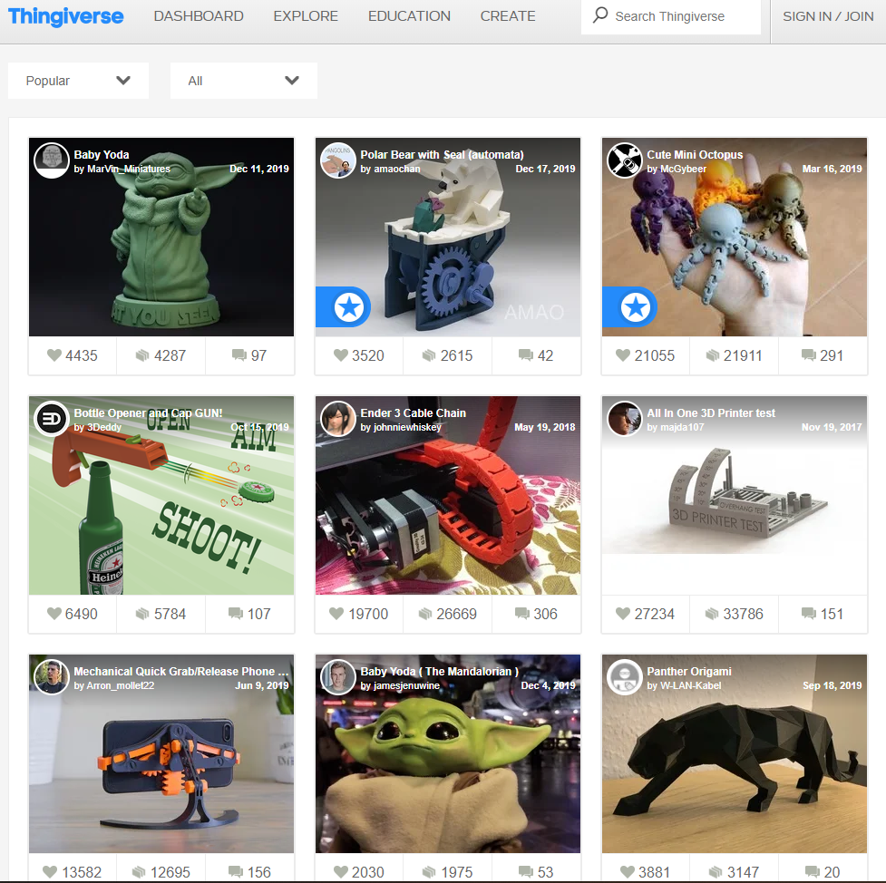

Though most people don’t frequently interact with 3D Printers and 3D-printed items, there are a wide variety of professionals, and even some consumers, who do. While we tend to associate 3D printing with plastic miniatures of our favorite TV and Cinema characters (and in fact Yoda holds 1st and 8th place in terms of popularity on 3D printable community Thingiverse), 3D printing has long been used to create dentures, jewelry, fashion, and masters of all kinds of objects to make molds and reproduce them in series.

The most popular items on 3D printable community Thingiverse – source: Thingiverse

And applications are rapidly expanding to medicine where functional organs are now being printed, and also food. When food is mentioned I suddenly remember that I included 3D printing as an important trend in a report on the cheese market in Spain, and how surprised I was at learning that many kinds of cheeses are especially good for 3D printing. So, to envision the full potential of 3D printing, both at present and in the future, we must challenge ourselves to go far beyond only thinking about plastic.

Google image search results for “3D printing food”.

The supporting ecosystem for the design of 3D printed items is surprisingly robust and accessible, with the internet awash with 3D design services and communities, many of which offer extremely affordable designs, and even many that are free to use and alter under Creative Commons licenses. And 3D printing design programs aren’t an exclusive realm of expert engineers and CAD designers, with many low-cost, or free, user-friendly programs available to novices:

Google image search for “programs for 3d printing design.”

A machine for each purpose

Extrusion printers are the most economical but offer the lowest quality. They work with a plastic thread that heats the material and passes it through an extruder that deposits it in thin layers on a tray where it cools and solidifies. These printers are very affordable and serve to create simple objects that do not need a lot of detail, and they enjoy the most robust support with the internet full of files that we can download for free and print inexpensively.

Stereolithography (SLA) printers work with a liquid synthetic resin that solidifies with ultraviolet light. The machine uses a small beam of light to solidify an object layer after layer. This technique requires much more printing time and more expensive material, and the printers are much more expensive and require lots of maintenance. The advantages are that they produce pieces of a very high quality because they can create layers of less than one third of a micron.

Selective Laser Sintering (SLS) printers can work with a variety of materials, from glass, steel, silver, gold, nylon, cellulose, etc. The materials come in the form of dust that is shot by a laser that solidifies it. SLS printers offer high quality but their high costs have reserved their use for engineers doing functional prototypes and small-scale manufacturing. However, costs have been coming down and there are now even desktop machines on the market.

Assorted items printed in Nylon by an SLS printer – source: Formlabs

Then what is the future?.. 4D Printing!

4D printing adds the extra dimension of time by creating matter that can be programmed to transform itself over time. Its potential applications are incredibly diverse and truly amazing, but it is still in its infancy and, since it is the future, I’ll explore it in more depth in a future post!